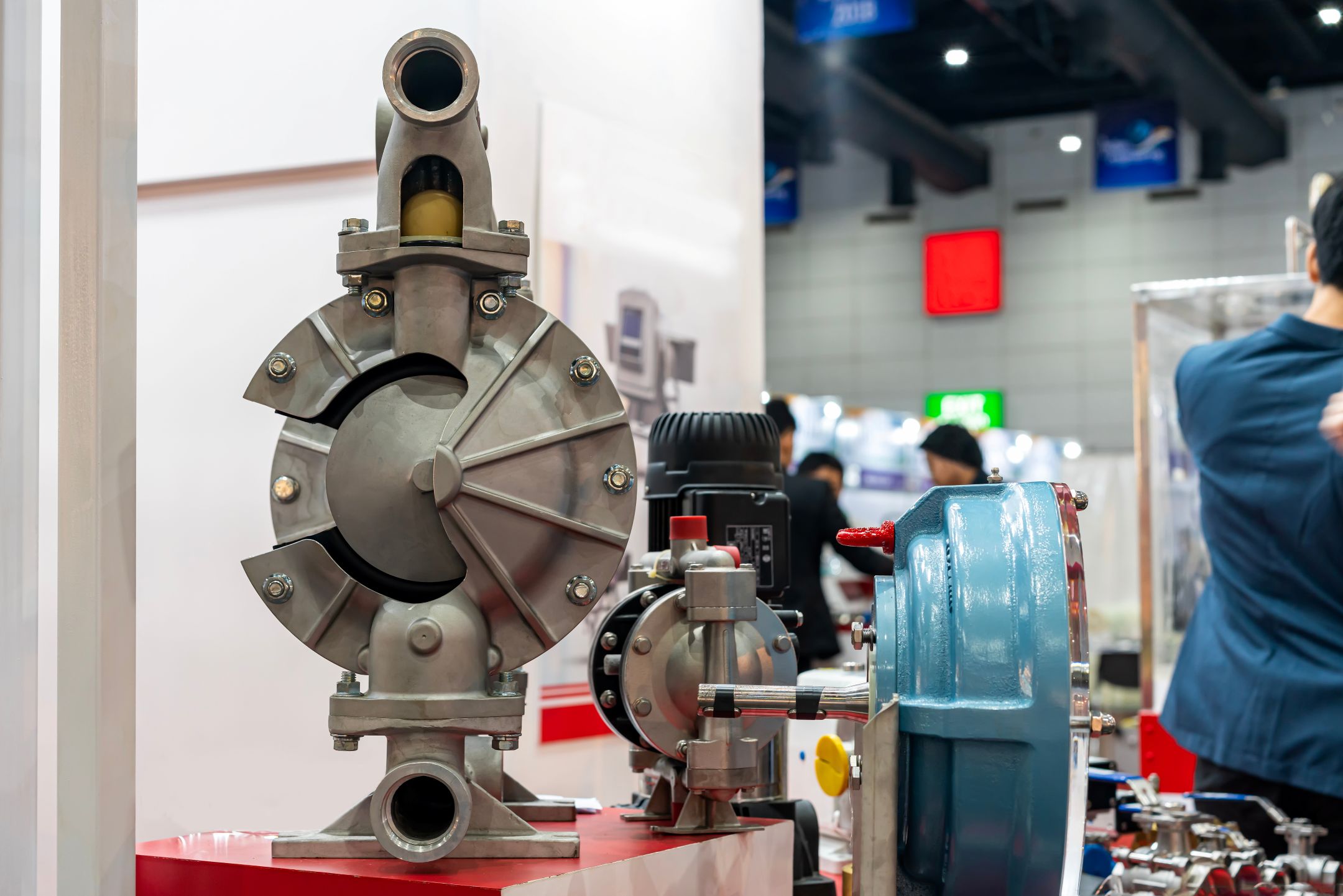

In retail manufacturing, maintaining product consistency is crucial for brand reputation, customer satisfaction, and regulatory compliance. One key technology that helps achieve this consistency is the diaphragm liquid pump. This type of positive displacement pump is widely used in industries such as food and beverage, cosmetics, pharmaceuticals, and chemicals due to its precision, reliability, and ability to handle a variety of liquids without contamination.

If you’re wondering how diaphragm liquid pumps enhance product consistency in retail manufacturing, here is a quick breakdown:

Consistent Flow Rates for Accurate Output

Retail manufacturing depends on consistent flow rates to ensure accurate filling and dosing. Diaphragm liquid pumps provide reliable, pulse-free flow across many production needs. This ability to regulate a range of flow rates ensures each unit is filled with precision, minimising underfills, overflows, and costly rework.

Unlike many other liquid pumps, diaphragm models offer exceptional stability during continuous operation. Their consistent performance results in fewer product rejects and ensures each batch meets the same standards, regardless of scale.

When looking for a diaphragm pump, do your homework to find the best suppliers. Read reviews, compare product specifications, and explore different resources to understand what each option offers. For instance, consider visiting knf.com/en/uk if you plan to source your pump from them. This research will help you choose a model that fits your production needs and supports consistent, high-quality results.

Broad Compatibility With Product Types

Retail manufacturers often deal with a wide variety of fluids, some of which are thick, others abrasive, corrosive, or sensitive to handling. Diaphragm liquid pumps adapt to all these materials with ease. Their compatibility with viscous or chemically reactive substances makes them ideal for chemical resistance applications and hygienic applications alike.

Whether you’re working with lotions, sanitisers, food syrups, or harsh detergents, these pumps handle everything without affecting the fluid’s integrity. Their durable pump component materials, such as polytetrafluoroethylene (PTFE) or stainless steel, offer optimal chemical resistance while supporting high-volume production demands.

Adaptability for Multi-Line Manufacturing

The ability to switch between product types quickly is essential in retail environments. Diaphragm pumps support fast changeovers with minimal risk of cross-contamination. Their adaptability also allows them to handle everything from microdosing to bulk filling without the need for equipment swaps.

Whether you’re using diaphragm water pumps, membrane pumps, or air-operated double diaphragm pumps, there’s a solution tailored to your operation. Popular models like 110V AC diaphragm pumps and 53-series pumps offer tailored configurations for specific use cases. This supports small-batch operations and large-scale production lines.

Gentle Handling for Product Integrity

Consistency is about quantity and maintaining the same product integrity across batches. Diaphragm liquid pumps preserve texture, colour, and composition by minimising shear stress during transfer. For shear-sensitive products such as emulsions, gels, or foaming liquids, this gentle approach prevents separation or degradation.

Diaphragm pumps handle fluids more delicately without compromising flow control than other technologies, such as peristaltic pumps. This results in a final product that looks and performs exactly as intended every time.

Low Maintenance for Maximum Uptime

Inconsistencies often arise from mechanical failures or irregular pump performance. Diaphragm liquid pumps combat this with long-lasting durability and simple maintenance.

Fewer moving parts, sealed pump chambers, and self-priming capability translate into less wear and fewer breakdowns. This means your production line stays up and running longer, with fewer interruptions.

In addition, many systems include a built-in pressure switch and pressure limit protection to maintain safe operation across varying suction heights and maximum flow rates. This added reliability helps reduce batch-to-batch variation.

Customisable Designs for Targeted Applications

Retail manufacturers benefit from the modular nature of diaphragm pumps. With various diaphragm pump models, you can choose the right pump head, material, and motor options to suit your fluid type and process requirements.

Whether you need a liquid transfer diaphragm pump, a gas pump, or a chemical transfer air motor, the options are vast and adaptable. This flexibility means you can optimise precision filling, chemical dosing, or aseptic fluid transfer solutions without buying multiple pieces of equipment.

Cost Efficiency Through Reliable Performance

Consistency helps protect profits, not just product quality. Problems like rejected batches, recalls, and manual fixes can quickly increase costs. Diaphragm liquid pumps support a steady flow, reduce unplanned downtime, and work well with different product lines. This makes them an innovative and cost-effective option for many businesses.

They also last a long time, need little maintenance, and run smoothly without stopping. These features help companies improve quality and efficiency while controlling costs.

Conclusion

Delivering a uniform product experience is crucial in retail manufacturing. Diaphragm liquid pumps enable that consistency by offering accurate flow control, material versatility, gentle handling, and unmatched reliability. They support various applications, from personal care to household cleaning products, and maintain high production standards with every cycle. For manufacturers seeking dependable fluid handling solutions that enhance quality and reduce risk, diaphragm pumps are an excellent option and a necessity.